Ion Beam Induced Nanocrystallization

Introduction

- It is well established that ion beam irradiation can stimulate the nucleation and grain growth in amorphous (a) silicon at relatively low temperatures . The silicon grain size distribution depends on the irradiation conditions such as ion dose and irradiation temperature.

- In the case of silicon carbide (SiC), with its low atomic mobilities and high thermal crystallization temperature of 800°C, it has been shown that ion implantation can stimulate the recrystallization process as well.

- Due to the lack of systematic investigations on the kinetics of ion-beam-induced- crystallization (IBIC) in a-SiC, in the present work, the dependence of the recrystallization process on the implantation parameters was studied .

Experimental

-

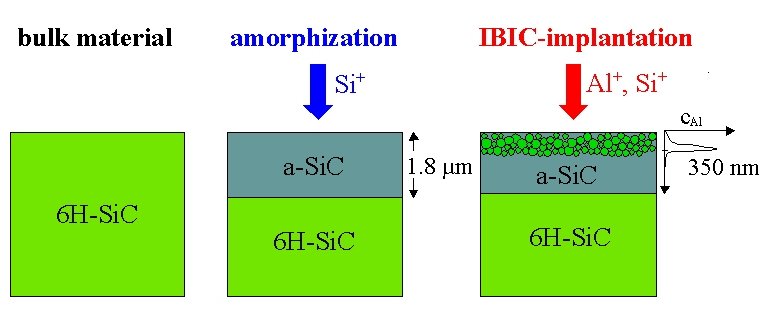

Substrate (bulk)material :

6H-SiC wafers (n type, (0001) orientation, Si surface )

-

Amorphization :

by 2 MeV, 5x1016 Si+/cm-2 implantation at room temperature 1.8 µm thick amorphous surface layer

-

IBIC-implantation :

300 keV (Al+,Si+) RP = (330,380) nm

dose rate : 1.0x1013. . . 3.3x1013Al+/cm2/s

dose range (3x1015 . . . 3x1017) Al+/cm2

temperature range (300 . . . 700 ) °C

Morphology

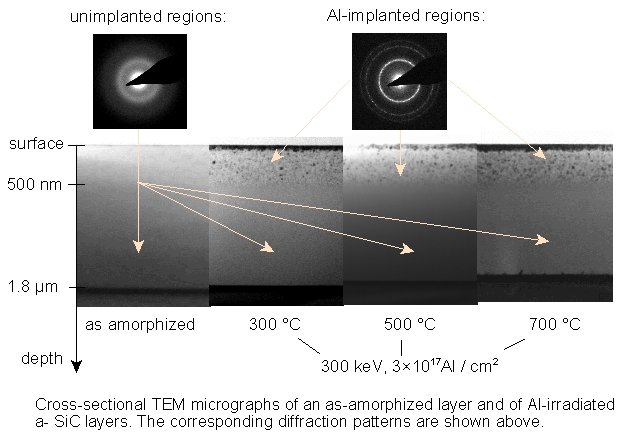

- Recrystallization takes place in the irradiated regions at 300?C, well below the SiC thermal recrystallization temperature of about 800?C.

- No sign of crystallization appears in unimplanted amorphous regions up to implantation temperatures of 700?C.

- The morphology of the recrystallized material completely differs from that after thermal crystallization.

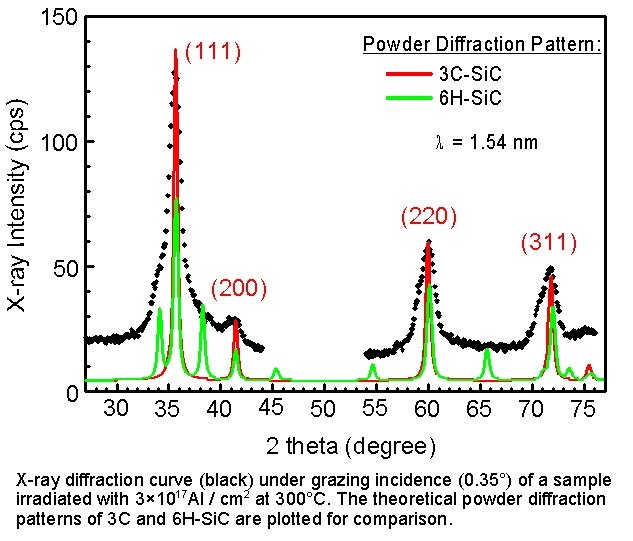

- Randomly oriented grains of 3C-SiC with almost spherical shape and a narrow size distribution around mean diameters ranging from 5 to 20 nm have been formed, as proved by X-ray diffraction.

Kinetics

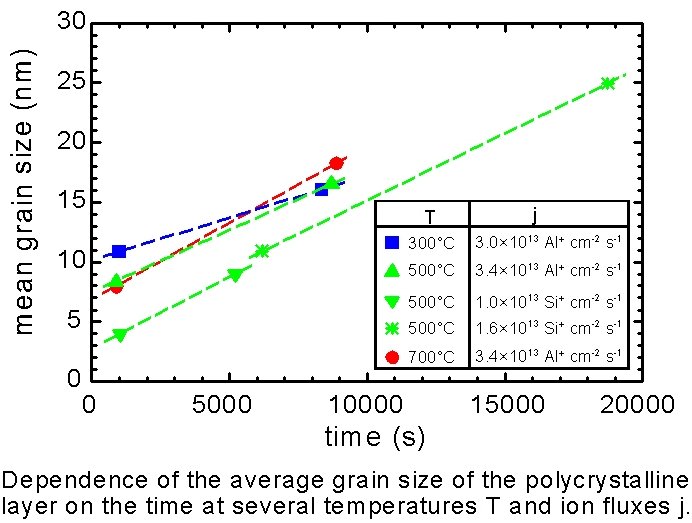

- The recrystallization is completed within a very narrow time window. Either almost completely recrystallized or still amorphous layers were found. Therefore, the nucleation and growth process could not be observed directly.

- From the extrapolation of the kinetics of the secondary grain growth to zero time the window of suitable parameters for the observation of nucleation and primary grain growth was esti- mated.

- The shift of the boundary of the recrystallized layer indicates the existence of a threshold energy for the onset of the crystallization at about 5x1022 keV/cm3.

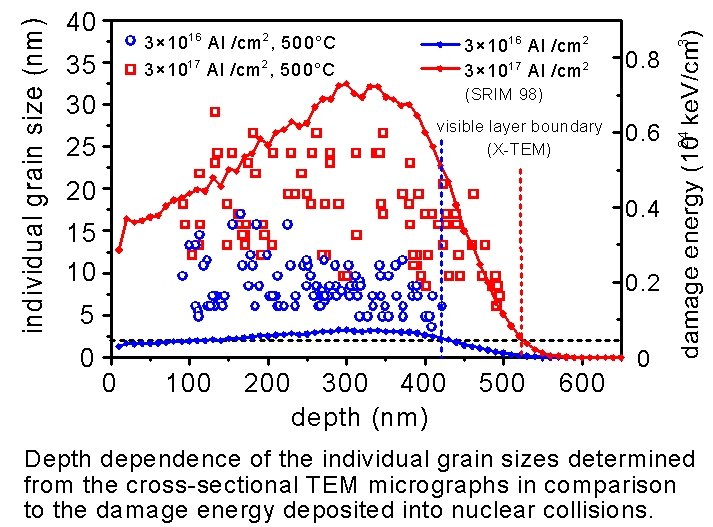

- No correlation between the individual grain size and the damage energy profile was found in the investigated parameter range.

Conclusions

- The recrystallization behavior of amorphous SiC layers under high dose implantation with Al and Si was investigated by XTEM and XRD measurements.

- The results show that ion irradiation strongly enhances the recrystallization process in a-SiC already at 300 °C, well below the thermal recrystallization temperature of about 800 °C. Randomly oriented grains of 3C-SiC, with almost spherical shape and mean diameters ranging from 4 to 25 nm, were formed during implantation.

- It was found that there is only a narrow time window for the observation of nucleation and primary growth. From the extrapolation of the kinetics of the secondary grain growth this time window was estimated.

.

URL of this article

https://www.hzdr.de/db/Cms?pOid=10920