| Machine |

Details |

Electron beam writer

Electron beam writer

RAITH 150 TWO

|

- Manufacturer: RAITH GmbH

- Applications:

- Electron source:

- 30 kV Schottky thermal field electron emitter ZrO/W

- Sample size: ≤ 4 inch wafer

- Smallest feature size: sub 8 nm

- Sample stage with laser interferrometer

- Height sensing and FBMS mode available

- GDSII editor for generation of complex structure design on several layers with individual dose factor assignment for single structrure elements

- NanoPECSTM software suite for the correction of proximitty effects

Responsible: Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

Electron beam writer

Electron beam writer

RAITH eLiNE plus

|

- Manufacturer: RAITH GmbH

- Applications:

- Nanolithography

- Imaging

- Nanoengineering

- Electron source:

- 30 kV Schottky thermal field electron emitter ZrO/W

- Sample size: ≤ 3 inch wafer

- Smallest feature size: sub 5 nm

- Sample stage with laser interferrometer

- 4 integrated nanomanipulators for e.g. nanoprobing

- Height sensing mode available

- GDSII editor for generation of complex structure design on several layers with individual dose factor assignment for single structrure elements

- NanoPECSTM software suite for the correction of proximitty effects

Responsible: Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

Deposition and annealing |

UHV evaporation tool UHV evaporation tool

BETty

|

- Manufacturer: BESTEC GmbH

- Base pressure <10-9 mbar

- E-gun evaporator (7 pockets)

- Thermal evaporator (Al)

- Temperature range 130 K – 600 K

- Tilt range ±45°

- Sputter gun (sample cleaning)

- Application: Metal film deposition

Responsible: Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

Evaporation tool Evaporation tool

LAB500

|

- Manufacturer: Leybold Optics

- Base pressure <10-7 mbar

- Substrate diameter: max. 100 mm

- Substrate thickness: max. 25 mm

- E-gun evaporator (4 pockets)

- Thermal evaporator (2 sources)

- Application: Metal film deposition

Responsible: Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

Atomic layer deposition

Atomic layer deposition

|

- Manufacturer: Ultratech/CambridgeNanotechALD

- Substrate size: ≤ 4 inch wafer

- Temperature: 80 - 350°C

- Materials:

- Al2O3

- HfO2

- SiO2

- mixed layers (on request)

Responsible: Dr. L. Rebohle, l.rebohle@hzdr.de, 0351 / 260 - 3368, Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

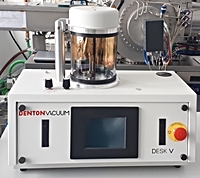

Sputter Coater

Sputter Coater

Desk V

|

|

Rapid thermal annealing

Rapid thermal annealing

JetFirst 100

|

- Manufacturer: Jipelec

- Substrate size: ≤. 4 inch wafer

- Temperature: ≤ 1300°C

- Gases: Ar, N2

Responsible: Dr. S. Winnerl, s.winnerl@hzdr.de, 0351 / 260 - 3522, Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

High vacuum oven

High vacuum oven

XERION X-TUBE

|

- Manufacturer: XERION ADVANCED HEATING® Ofentechnik GmbH

- Sample size: ≤ 4 inch wafer

- Temperature range: ≤ 800°C

- Pressure: down to 4*10-7 mbar

- Gas: N2

- Ramp rates for heating up and cooling down

Responsible: Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

Etching and cleaning |

Reactive ion beam etcher

Reactive ion beam etcher

IonSys 500

|

- Manufacturer: ROTH & RAU AG

- Applications:

- Non-selective etching by sputtering with Ar gas

- Anisotropic etching of:

- Metals

- Magnetic stacks

- SiO2

- Sample size: ≤ 6 inch wafer

- Ar source

- Etch gas: CF4

- Helium backside cooling

- Sample tilting: ≤ 90°

- Sample rotation: ≤ 10 rpm

- Secondary Ion Mass Spectrometer (SIMS) manufactured by Hiden Analytical, UK for end point detection

Responsible: Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

Plasma cleaner

Plasma cleaner

PICO

|

- Manufacturer: DIENER ELECTRONIC GmbH + Co. KG

- Applications:

- Activating of semiconductors

- Cleaning of semiconductors

- Etching of semiconductors

- Plasmapolymerisation

- Sample size: ≤ 4 inch wafer

- Gases: O2, Ar

, N2

- Frequency: 2,45 GHz

- Power: 0 - 300W

- Faraday box for electrical sensitive components

- Piranisensor is measuring the pressure below 10 mbar

- Power display of the generator

- Timer for setting the process time up to 999,9 min

Responsible: Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

Electrical characterisation |

Cryogenic probe station

Cryogenic probe station

CPX-VF

![]()

|

- Manufacturer: LAKESHORE

- Applications:

- C-V measurements

- I-V measurements

- 4-Probe measurements

- Hall measurements

- Microwave measurements

- Electro-optical measurements

- all measurements can be combined with out-of-plane vertical field superconducting magnetic measurements

- Sample size: ≤ 2 inch wafer

- Magnetic field: ∓ 2,5 T

- Orientation of the magnetic field: vertical out-of-plane

- Temperature range: 4.5 K – 400 K

- Available sample holder:

- grounded sample holder

- coaxial sample holder

- tiltable sample holder

- Orientation of the magnetic field can be changed to in-plane

- Measuring instruments:

- AGILENT 4156C Precision Semiconductor Parameter Analyzer

- LakeShore 625 Superconductiong magnet power supply

- LakeShore 340 Temperature controller

- LakeShore 332 Temperature controller

- Incoupling of a laser signal (λ = 473nm / 785nm) possible

- Multiple radiation shields for best low temperature performance

- Minimize sample condensation during cool-down

- True 90° probing

Responsible: Dr. A. Erbe, a.erbe@hzdr.de, 0351 / 260 - 2366>

|

Cryogenic probe station Cryogenic probe station

TTP-4A

![]()

|

- Manufacturer: LAKESHORE

- Applications:

- C-V measurements

- I-V measurements

- Microwave measurements

- Electro-optical measurements

- Sample size: ≤ 2 inch wafer

- Temperature range: 4.5 K – 400 K

- Available sample holder:

- grounded sample holder

- coaxial sample holder

- Measuring instruments:

- AGILENT 4156C Precision Semiconductor Parameter Analyzer

- AGILENT 34410A Digital Multimeter

- KEITHLEY 2400 Source Meter

- LakeShore 332 Temperature controller

- Incoupling of a laser signal (λ = 473nm / 785nm) possible

- Radiation shield for best low temperature performance

- Minimize sample condensation during cool-down

- True 90° probing

Responsible: Dr. A. Erbe, a.erbe@hzdr.de, 0351 / 260 - 2366>

|

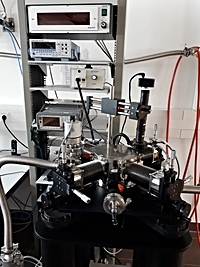

Mechanically controlled Mechanically controlled

break junction setup

![]()

|

- Applications:

- Electrical characterization of molecular structures

- at room temperature

- in liquid environment

- Currently investigated molecules:

- Selenium metal complexes

- Polythiophenes

- Bucky-bowl structures (e.g. Corannulene)

- Currently investigated solvents:

- Current measurement in the range of Femto-Ampere due to electrical and magnetic shielding technology

- 4 setups

-

Responsible: Dr. A. Erbe, a.erbe@hzdr.de, 0351 / 260 - 2366

|

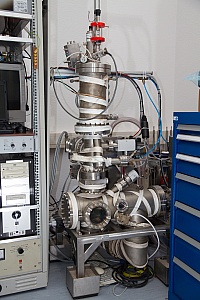

Cryogenic UHV Cryogenic UHV

break junction setup

|

- Applications:

- I-V measurements

- Ploting histograms of the conductance

- Inelastic electron tunneling spectroscopy (IETS)

- Point-contact spectroscopy (PCS)

- Temperature range: 5 K – 300 K

- Pressure (at low temperatures): 5*10-5 mbar

- In situ deposition of molecules into the break junctions

- Via thermal evaporation of e.g. C60

- Depostion rate: 0,2 Å/s - 0,6 Å/s

- Thicknesses of ¼ up to 1 monolayer

- Measuring instruments:

- KEITHLEY 2400 Source Meter

- KEITHLEY 6430 Sub Femtoamp Remote Source Meter

- LakeShore 331 Temperature controller

- YOKOGAWA 7651 Programmable DC Source

Responsible: Dr. A. Erbe, a.erbe@hzdr.de, 0351 / 260 - 2366

|

Optical characterisation |

Optical tweezers

Optical tweezers

|

- tool for ...

- Application: ...

Responsible: ...

|

Sample preparation and lab equipment |

Laser cutter

Laser cutter

skylaser MARK 20

|

- Manufacturer: PFEIFER technology & innovation

- Applications:

- Surface graving and labeling

- Cutting of wood, plastics, (to some extend) Silicon

- Sample size: up to 110 x 110 cm²

- Alignment accuracy: ~ 0,1mm

- Laser power: 20 W

- Laser source: Ytterbium pulsed fiber laser

- Wavelength: 1064nm

- Speed: max. 10.000 mm/s

- Frequency: 20 - 80kHz

Responsible: Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

Spin Coater

Spin Coater

LabSpin 6

|

- Manufacturer: SÜSS MicroTec

- Applications:

- Spin coat resists for electron beam lithography

- Sample size: ≤ 4 inch wafer

- Rotation speed: ≤ 8000 rpm

Responsible: Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

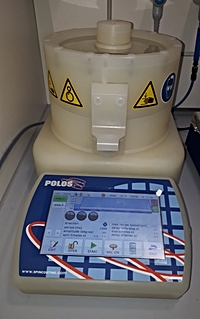

Spin Coater

Spin Coater

POLOS Spin150i

|

- Manufacturer: SPS Europe

- Applications:

- Sample size: ≤ 4 inch wafer

- Rotation speed: ≤ 12.000 rpm

Responsible: Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

Hotplate

Hotplate

HP-20D

|

- Manufacturer: witeg Labortechnik GmbH

- Applications:

- Pre/Post bake of EBL resist

- Sample cleaning

- Lift off processes

- Sample size: 180 mm x 180 mm

- Temperature: ≤ 380°C

Responsible: Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

Hotplate

Hotplate

Velp Scientifica

|

- Manufacturer: VelpScientifica

- Applications:

- Pre/Post bake of EBL resist

- Sample cleaning

- Lift off processes

- Sample size: 180 mm x 180 mm

- Temperature: ≤ 550°C

Responsible: Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

Optical microscope

Optical microscope

OPLYMPUS BX51

|

- Manufacturer: OLYMPUS GmbH

- Magnifications: 5x, 10x, 20x, 50x, 100x, 250x

- Dark field and bright field mode

- Transmitted light and reflected light mode

- Taking images with the installed camera (Carl Zeiss Axio Cam MRc)

Responsible: Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

Ultrasonic bath

Ultrasonic bath

USC 300D

|

- Manufacturer: VWR

- Ultrasonic frequency: 45 kHz

- Ultrasound power: 32 - 80 W (9 power levels)

- Temperatur: ≤ 80°C

- Time: ≤ 99 min

- Degas function

Responsible: Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

Multi-functional orbital shaker

Multi-functional orbital shaker

PSU-20i

|

- Manufacturer: bioSan

- Orbital rotation:

- Speed control range: 20 -250 rpm

- Increment: 5 rpm

- Time setting range: ≤ 250 s per cycle

- Reciprocal motion:

- Amplitude range: 0 - 360°

- Increment: 30°

- Time setting range: ≤ 250 s per cycle

- Vibro motion:

- Amplitude range: 0 - 5°

- Increment: 1°

- Time setting range: ≤ 5 s per cycle

- Load: max 8 kg (below 150 rpm)

Responsible: Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

High precision scale

High precision scale

ABJ120

|

- Manufacturer: Kern

- Max. weight: 120 g

- Min. weight: 10 mg

- Readability: 0,1 mg

Responsible: Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

Fume hood

Fume hood

Secuflow

|

- Manufacturer: Waldner

- Volume flow: at least 330 m³/h

Responsible: Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

Laminar flowbox

Laminar flowbox

|

- Manufacturer: BDK Luft- und Reinraumtechnik GmbH

- Filter class: H14

Responsible: Dr. Y. Georgiev, Y.Georgiev@hzdr.de, 0351 / 260 - 2321

|

Planned experimental setups |

Asynchronous Optical Sampling (ASOPS)

Asynchronous Optical Sampling (ASOPS)

|

- Application

- Optical characterization of nanomechanical resonators

Responsible: Dr. A. Erbe, a.erbe@hzdr.de, 0351 / 260 - 2366

|