Formation of gas bubbles in liquid metals

If gas bubbles are injected into a liquid metal characterised by a large surface tension

one should be care to get a good wetting between the fluid and the surface of the gas

injector. Otherwise, the gas would try to spread out along this interface to form gas

layers. A control of the bubble size and formation rate becomes difficult. The comparison

between experiment and theoretical models describing bubble formation processes requires

an ideal wetted gas injector.

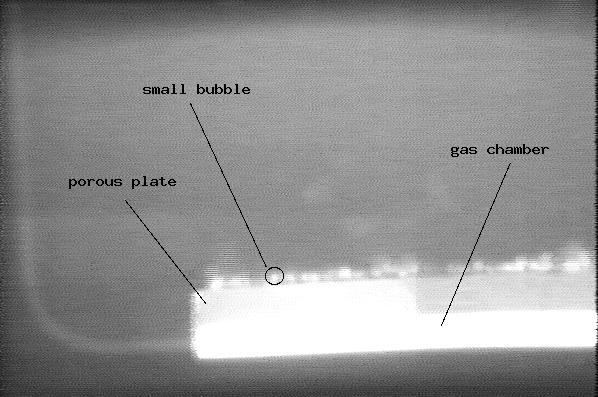

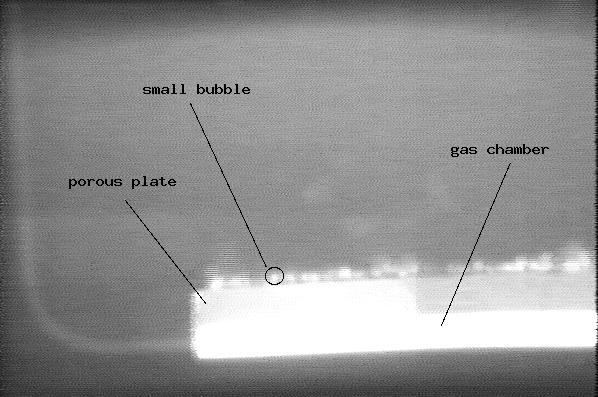

The bubble formation in the eutectic alloy InGaSn has been studied at the surface of a

gas injector made from sintered metals with a mean porosity of a few microns.

X-ray measurements have been used to directly observe the

resulting gas bubbles rising in the liquid metal.

The following figure demonstrates the formation of a gas layer around the whole injector,

if the surface is not wetted by the liquid. Only large bubbles release if the buoyancy

force becomes strong enough to balance the surface tension force. In this case the diameter

of the resulting bubbles does not depend on the pore size of the porous media.

If the injector surface is wetted by the liquid metal a quite different behaviour of bubble

formation will be found: Many small bubbles are formed along the whole surface.

Indications for the development of a gas layer are not visible.

back to Svenīs Hompage