High-Energy Ion Implantation

High-energy ion implantation has been well-established in production technology of a number of semiconductor devices. Known advantages of targeted doping, defect creation, or a combination of both are utilized with high-energy ion implantation.

High-energy ion implantation has been well-established in production technology of a number of semiconductor devices. Known advantages of targeted doping, defect creation, or a combination of both are utilized with high-energy ion implantation.

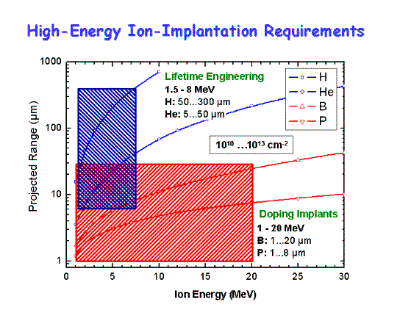

High ion energies of typically some megaelectron-volts (MeV) induce high ion penetration depths in material, thus, facilitating buried doping or defect profiles, unlike any other technology.

Low fluences of 1010 to 1013 cm-2 in typical application fields make the high-energy ion implantation also financially attractive.

Typical application fields of high-energy ion implantation include:

- Implantation of light ions (H, He) to improve the switching behavior in power electronic semiconductor devices (power diodes, thyristors, or power MOSFETs)

- Implantation of doping elements (H, B, P, As, ...) to tune field strength distributions in photodiodes, particle detectors or high-voltage devices

- Implantation of heavy ions to improve emission characteristics of laser diodes

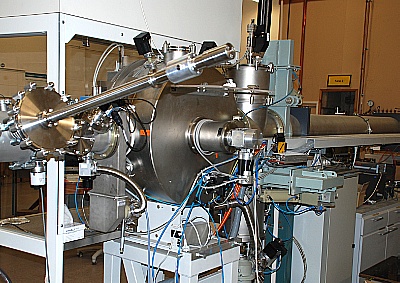

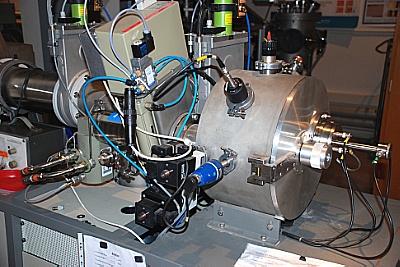

Following implantation chambers and wafer handling systems are offered to perform high-energy ion implantation at our 6 MV Tandetron and 3 MV Tandetron high-energy ion accelerators:

6 MV Tandetron

|

|

High Voltage Engineering Europa B.V. |

|

|

Duoplasmatron model 358 + Li charge exchange channel (only for He-) Cs sputter source, model 860C |

|

|

0.3 - 6 MV |

|

|

0.6 - 50 MeV (depending on charge state) |

(I) Channel 3: Single wafer implantation chamber

|

|

|

x, y electrostatic (f ≈ 1 kHz) |

|

|

wafers or other planar samples |

|

|

up to 150 mm wafers |

|

|

7° (other on request) |

|

|

no cooling, typically room temperature |

|

|

starting from 1x1010 cm-2 |

|

|

class 6 (DIN EN ISO 14644) |

|

|

typically 20 per h (depending on fluence) |

|

(II) Channel B2: Automated wafer handler

|

|

|

≤ 150 mm: x, y electrostatic;

>150mm, combination of electrostatic/mechanic |

|

|

wafers only |

|

|

up to 200 mm wafers |

|

|

7° (other on request) |

|

|

no cooling, typically room temperatur |

|

|

starting from 1x1010 cm-2 |

|

|

class 5 (DIN EN ISO 14644) |

|

|

up to 50 per h (depending on fluence) |

|

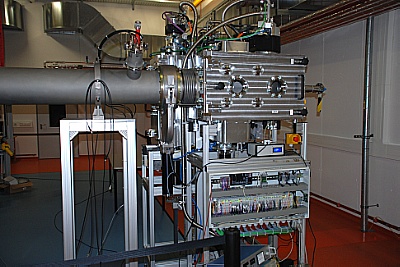

3 MV Tandetron

|

|

High Voltage Engineering Europa B.V. |

|

|

Duoplasmatron model 358 + Li-charge exchange channel (only for He-) Cs sputter source, model 860C |

|

|

0.1 - 3 MV |

|

|

0.2 - 8 MeV (depending on charge state) |

(I) Channel 2: Single wafer, large implantation chamber

|

|

|

x, y electrostatic (f ≈ 1 kHz) |

|

|

wafers or other planar samples |

|

|

up to 125 mm wafers |

|

|

7° |

|

|

no cooling, typically room temperature |

|

|

starting from 5x1010 cm-2 |

|

|

class 5 (DIN EN ISO 14644) |

|

|

typically 20 per h (depending on fluence) |

|

(II) Channel 2: Single wafer, small implantation chamber

|

|

|

x, y electrostatic (f ≈ 1 kHz) |

|

|

wafers or other planar samples |

|

|

up to 100 mm wafers |

|

|

7° or 0° |

|

|

from LN2 up to 800 °C |

|

|

starting from 5x1010 cm-2 |

|

|

not controlled |

|

|

typically 10 per h (depending on fluence) |

|

(III) Channel 4: Semi-automated wafer handler EATON NV-10

|

|

|

x, y (mechanic) |

|

|

wafers only |

|

|

100 mm, 125 mm and 150 mm wafers |

|

|

7° |

|

|

no cooling, typically room temperature |

|

|

starting from 1x1012 cm-2 |

|

|

class 5 (DIN EN ISO 14644) |

|

|

up to 100 per h |

|

High-energy ion implantation has been well-established in production technology of a number of semiconductor devices. Known advantages of targeted doping, defect creation, or a combination of both are utilized with high-energy ion implantation.