Boron implantation into hard metals

(This work is supporting by the EC, contract BRPR CT97-0380.)

- wear and friction behaviour

- tribological properties

- strength and hardness

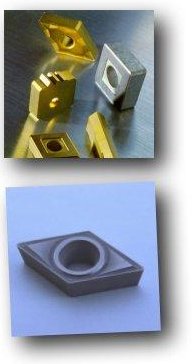

This study demonstrates that hardness and wear characteristics of the hard metal H3 (15%Co, WC, grain size ~1µm) can be improved by boron implantation. It wasn't detected a new phase formation. So it seems that the improvement of mechanical properties is caused by radiation induced defects.

Figure: Wear results of a 3 mm diameter tungsten carbide sphere,

sliding under a load of 1 N on cemented WC (H3) samples after implantation

with 40 keV boron at a fluence of 5x1017 ions/cm2

at different temperatures