References

Below are some examples of major projects that were developed and assembled with significant involvement of the Central Department of Research Technology.

Evaluation unit for muon detector

The muon detector was designed to perform, among other things, tomography on castor containers. The aim is to check their contents without opening them and exposing oneself to radiation. In muon tomography, differences in the density of matter are visualized.

The evaluation unit for the muon detector was developed in the Central Research Technology Department. The main focus of development was the most accurate possible measurement of the times of an interaction between muons and the muon detector and the scalability. For this purpose, the detector channels are operated synchronously on all acquisition units. From a single acquisition unit (16 detector channels) up to any number of racks (with 10 acquisition units each), they can be operated synchronously with a time resolution of 10 ns.

Control of the system is handled by a C++ application, providing a user interface in the form of a web page (based on Vue.js) for control and communication via WebSockets.

- Project number: AAA00498.001

- Project completion date: mid 2023

- An FPGA design from the Central Research Engineering Department is used in each module.

Capacitor pulse system and pulse field coils for high-field magnet laboratory

To generate the highest pulsed magnetic fields, the world's most powerful pulse generation facility to date has been set up at the High Field Magnet Laboratory in Dresden. The pulse discharge capacitor banks (pdf) and the high-field coils (pdf) were developed for this purpose in the Central Research Technology Department.

Subproject: Tripple Coil (Coil)

- Project number: AAA00589.001

- Project completion date: 2023

- After delivery of the Tripple Coil, the record attempt to generate the world's highest magnetic field will be made with the coil. The scientists from the High Field Magnet Laboratory are targeting a magnetic field strength of 100 tesla.

Research facility DRESDYN

The DREsden Sodium facility for DYNamo and thermohydraulic studies (DRESDYN) is built for large scale liquid sodium experiments. The hydromagnetic dynamo effect which occurs for instance in the earth core will be investigated as well as various energy related technologies. The facility is divided in two sections: The sodium storage tanks in which the sodium is also melted and the actual experimental area. The main component is the world-wide first precession dynamo. This rotational container with the liquid sodium is mounted in a slewing mechanism on a rotating platform. During the experiment it will be rotating around its central axis with up to 600 rpm and around an inclined axis with up to 60 rpm by rotating the platform. Sodium gets over a heated pipe system from the storage tanks to the experiment and back. The Central Department of Research Technology designs the mechanical components and assembles them in cooperation with industrial partners. The Central Department of Research Technology conducts also the project management of the entire plant control system and the machine safety system.

Liquid metal test facility LIMMCAST

The experimental plant LIMMCAST was built at the Institute of Fluid Dynamics for the investigation and optimization of continuous casting. This facility was projected by the Central Department of Research Technology according to the specifications of the scientists. It was assembled together with industry partners and put into operation. Moreover the Central Department of Research Technology is permanently involved in the extension and further developments.

Super-SIMS beamline

Super-SIMS (SIMS = Secondary ion mass spectrometry) - also called Accelerator-SIMS or Trace Element AMS (TREAMS) - is an ultrasensitive analytical method for the determination of stable elements and isotopes. Actually, a Super-SIMS-Set-up is developed at the HZDR ion beam centre by connecting a conventional SIMS-source to a 6 MV tandem accelerator. The central department of research technology took on the instrumentation, electrical planning, the development of the control software as well as the electric wiring of the vacuum section between the SIMS-source and the accelerator. This contains the usual vacuum components but also some high voltages power supplies to affect the ion beam. Furthermore opportunities for improvement of the control system are evaluated and realized by the central department of research technology.

Radionuclide distribution system for ZRT

Since 2018, the ZRT - Centre for Radiopharmaceutical Tumor Research (ZRT) has been operating a new circular accelerator (cyclotron) for the production of various radionuclides, which are required as a basis for the research and production of radioactive drugs. The task assigned to Research Engineering was to develop and implement a control system with a user interface for several operator stations, as well as to design and manufacture the necessary mechanical assemblies for transporting the radioactive substances. The resulting radionuclide distribution system (RNV) enables the transport of gaseous and liquid radionuclides directly from the target at the cyclotron to the desired PET box in the laboratory or clean room. A selection of the desired target box can be made before each transport order. In contrast to gaseous radionuclides, where a complete target content is always transported to the target, liquid radionuclides can be dosed to several targets. For this purpose, the complete content is first temporarily stored, the activity is determined and then transported on in parts. The transport of the liquid or gaseous substances takes place in capillary lines by means of pressurization by a transport gas. The RNV enables the execution of manual or automated transport orders. These can be initiated from different operating locations. The control system independently takes care of ensuring the selected transport route and all necessary shielding.

Efficient waste water treatment - SEBAK

An experimental plant (SEBAK) for optimizing sewage plant aerator optimization was assembled in the Institute of Fluid Dynamics. The Central Department of Research Technology conducts the project management including the measurement technology and the plant control system.

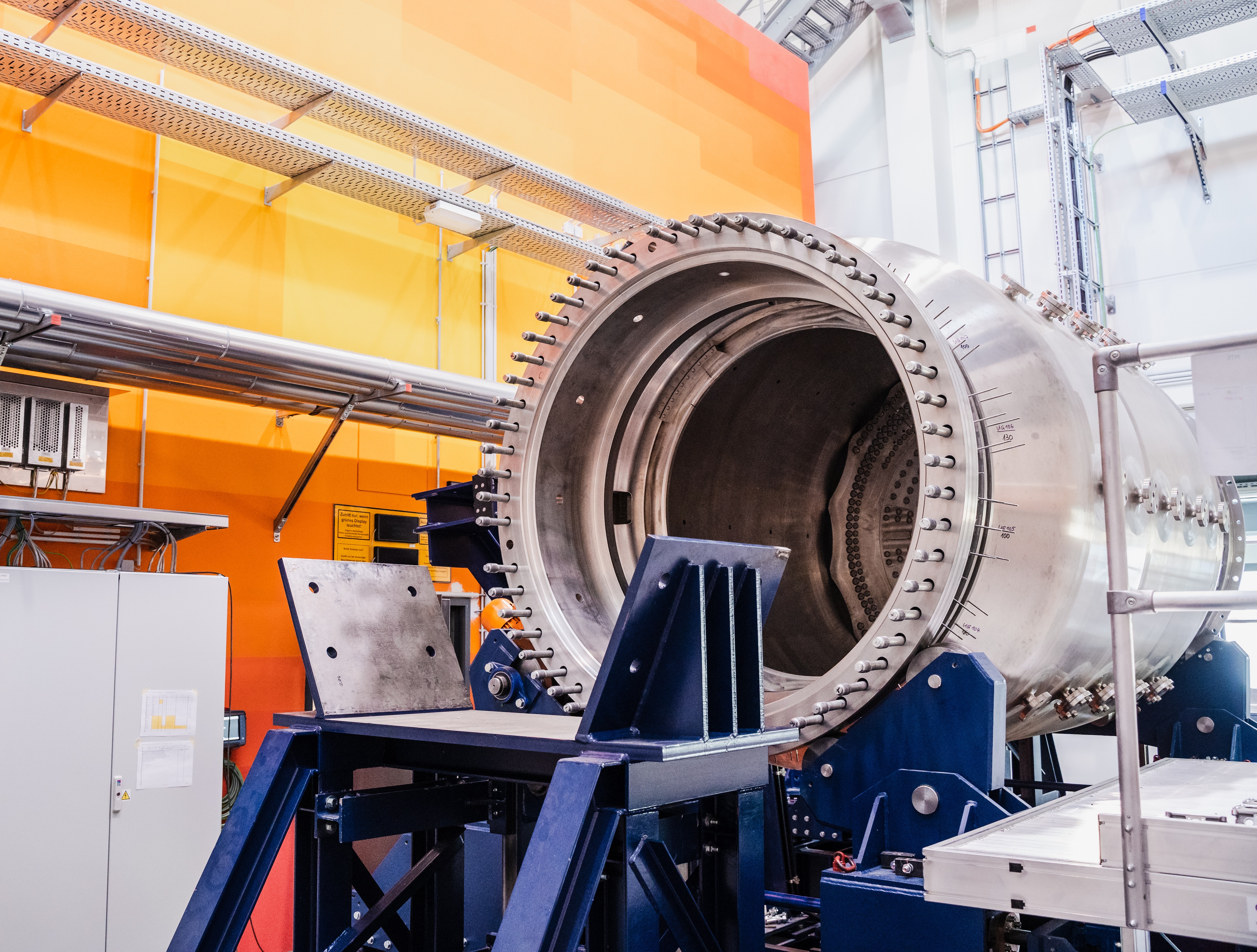

Superconducting linear accelerator at the radiation source ELBE

The radiation source ELBE has been built as the most important large-scale facility at the institute of Radiation Physics of the HZDR . The first stage (pdf) was designed, projected and put into operation under the leadership of the Central Department of Research Technology. This containted the thermionic electron source (Gun) and the injector (pdf), the superconducting accelerating modules (pdf) , the beam control, the first FEL, a photo neutron target (pdf) as well as the control and communication system including the personal and machine safety system. Moreover the Central Department of Research Technology is permanently involved in the extension and further developments. So a beam position monitor (BPM/DCM) with integrated differential current monitor (DCM) has been developed with a large dynamic range. A small batch has been produced.