Liquid metal multiphase flows

Multiphase flows play an important role in a number of technological processes

in metallurgical and chemical industries. Gas bubbles are injected into liquid

baths in order to stirr the fluid, because often times a better homogeneization

(temperature, concentration) or the generation of a distinct flow structure

is desired.

One has to look for suitable methods to control the properties of such kind

of flows. The utilization of magnetic fields seems to be an attractive way

to affect the spatial distribution of bubbles or the momentum transfer

between the gas and the liquid.

On the other hand it is necessary to look for new measurements methods

that can be used in such multiphase flows that include opaque liquid metals.

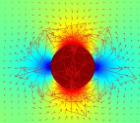

Elektromagnetic Separation

Electromagnetic fields enable contactless separation of material mixtures using

differences in the magnetic or electrical material properties. The task is to develop promising approaches for the successful application of electromagnetic methods for process control and material processing.

More

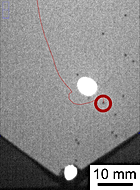

Flotation of non-metallic inclusions in liquid metals

The removal of non-metallic inclusions from liquid metal alloys by means of gas bubbles is important to ensure clean and high-quality structural materials. The FLOTINC project aims for a better understanding of interactions, e.g. collision, attachment and detachment, between bubbles and inclusions.

More

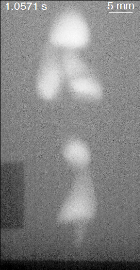

Liquid metal multiphase flows

Multiphase flows with a compressible disperse phase, i.e. gas bubbles, are a major challenge for research and technology development as they tend to form very complex flow patterns. Measurements in liquid metals are challenging, but, indispensable because of distinct differences in material properties compared to water.

More

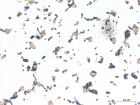

Liquid metal route for creation of Metal Matrix Composites (MMC)

Dispersion of particles to produce metal matrix nanocomposites can be achieved by means of ultrasonic vibration of the melt using ultrasound transducers, however, this method is not feasible for production of steel composites because of the harsh environment. The aim of the project is to create cavitation in a contactless way.

More