Research Highlights 2010

- Using Nature as a Role Model

- Fighting Cancer Together

- Pursuing Whirling Gas Bubbles

- Current Flow at the Nano Level

- Positrons Sniff Out Defects

- Customized Magnetic Fields

Using Nature as a Role Model

Using Nature as a Role Model

Scientists break new ground in internal cancer radiation

Due to the aging population, the cancer-related mortality in developed industrial countries is constantly increasing. For the treatment of cancer, physicians primarily focus on three strategies: Surgery, chemotherapy, and external radiation. However, if cancer cells have already been detached from a tumor and deposited metastases elsewhere in the body, then the chances for recovery are significantly reduced. On their way towards finding a method which helps detect and efficiently treat metastases, the Rossendorf radiopharmacists have taken a big step forward. Their vision is that cancer could be irradiated not only in the classic way from the outside, but also from the inside with the help of radioactive substances. Thus, the rays could be targeted better at cancer cells, and healthy tissue would be protected.

A very effective possibility that radioactive substances are able to detect tumors and attach themselves to these tumors is based on the use of specific antibodies. But it takes several days before they accumulate in the cancer tissue. It is, thus, possible that radioactive antibodies unintentionally expose the organism to radiation. In order to circumvent this, the researchers are developing a subtle method: First, non-radioactive antibodies are injected. The radioactive component is only administered after these antibodies have accumulated at the cancer cells. This component then quickly finds its way into the tumor where it unites with the antibodies.

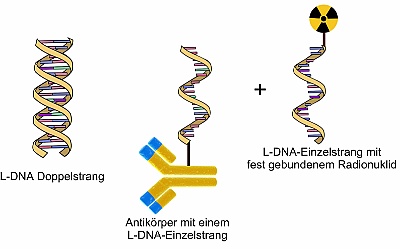

But how can the radioactive component find the antibodies? The researchers use nature as a role model with a system that mutually recognizes itself: Two complementary, single DNA strands “A” and “B.” The antibodies are equipped with “A” while “B” is labeled radioactively. Once the two single strands meet, a very stable bond is rapidly created just like a zipper. The scientists, though, do not use any naturally occurring DNA, but rather its mirror image. Thus, strand “B” can only connect to strand “A” and not to any other binding sites inside the body. Within the scope of his doctoral dissertation, Christian Förster improved the radioactively labeled DNA in such a way that this DNA can optimally distribute and bind itself inside the body. This is a big step forward on the way towards internal radiation.

- Publication: C. Förster, R. Bergmann et al., Radiolabeled L-oligonucleotides with tunable pharmacokinetics – A suitable complementary system for pretargeting approaches, Nuclear Medicine and Biology 37(6), 706 (2010), DOI: 10.1016/j. nucmedbio.2010.04.100

- Contact: Christian Förster (Institute of Radiopharmacy)

Fighting Cancer Together

Fighting Cancer Together

For the first time ever, a Dresden research group irradiates cancer cells with laser accelerated protons and analyzes the effects

Today, cutting edge research means teamwork. In order to gain new insights and create the foundation for progressive technologies, researchers also depend on close cooperations with colleagues who are active in other sectors. One such successful and promising example is the cooperation of the Rossendorf laser physicists with physicists, biologists, and physicians at Dresden’s OncoRay center. The HZDR researchers are committed to the question of how charged particles can be accelerated with laser light to such high energies that they can be used in radiation therapy. It is their objective to develop compact devices for particle therapy in cancer patients.

Laser particle acceleration is still quite a new sector which has been researched at the HZDR since 2006. The project team which was founded back then has now grown into a department with more than 20 employees. They operate the high intensity laser DRACO with which they generate ultrashort, pulsed proton beams. Protons are positively charged particles and particularly suited for radiation therapy since they release their energy primarily inside the tumor. That is why they are used for inoperable tumors inside organs sensitive to radiation. The acceleration of protons with laser light requires significantly less space than with conventional, large-scale accelerator systems. A mature technology based on laser accelerated particles, so the vision and mission of the researchers, could be available in many hospitals with a radiation therapy unit in the future. At the moment, the particle therapy can only be used in a few centers around the globe.

Last year, the research center managed for the first time ever to irradiate cancer cells with laser accelerated protons and to examine their effect. This success only became possible in the joint OncoRay network: The team of scientists succeeded in generating a stable proton beam, measuring the precise dosage released to the cells, and determining the particles’ biological impact from the extent of cell damages. The future challenge will be to optimize the properties of proton beams in such a way that they are clinically usable for cancer therapy. Currently, the laser physicists can generate proton energies of up to 20 mega electron volts. This is the minimum range for beams capable of penetrating tissue. Proton energies of up to 60 mega electron volts were already achieved by HZDR researchers on a larger laser system at the US American Los Alamos National Laboratory.

- Publication: S. D. Kraft et al., Dose dependent biological damage of tumour cells by laser-accelerated proton beams, New Journal of Physics 12, 085003 (2010), DOI: 1088/1367-2630/12/8/085003

- Contact: Dr. Stephan Kraft (Institute of Radiation Physics)

Pursuing Whirling Gas Bubbles

Pursuing Whirling Gas Bubbles

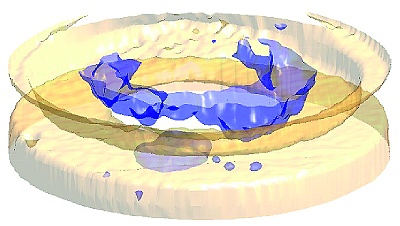

The Helmholtz-Zentrum Dresden-Rossendorf creates ultrafast three-dimensional images of complex mixed flows

When mixtures of gas and liquids flow, there’s turbulent confusion. For example, gas bubbles constantly change their shape, dissipate and consolidate, whirl around one another, or accumulate in front of obstacles. These processes can be observed exactly with the ultrafast three-dimensional X-ray tomography which was developed by Dr. Martina Bieberle and her colleagues. The procedure delivers images from the inside of a metal tube at millisecond intervals; thus, showing, for example, how a flowing mixture of air and water passes through a bottleneck. While some of the air bubbles essentially get stuck in front of the narrowing, other bubbles penetrate it at high speed and are severely deformed in the process.

Until now, the electron beam X-ray tomograph ROFEX has only been able to create cross-sectional images of a tube through which a fluid passes; in other words, two-dimensional images. Now, though, the researchers are able to deflect the beam in such a way that X-rays can penetrate the examined object at several levels until they are finally caught by a detector. Up to 500 volume images per second can be produced with 3D tomography. With this method it is possible to precisely ascertain how quickly the air bubbles flow through the water, what size they have, and how they change their shape. This method permits the analysis of various multiphase mixtures. The images are to deliver, for example, the database for simulations which help predict the behavior of complex flows.

Gas-liquid mixtures flow through pipelines in many technical facilities, whether it be in chemical process engineering, in power plants, or the extraction of mineral oil. Thus, the size and shape of the gas-liquid interface have a significant impact on how materials and heat are transmitted or how high the mechanical stress is on the receptacle walls which is why these factors must be taken into account when planning such facilities.

- Publication: M. Bieberle et al., Ultrafast three-dimensional X-ray computed tomography, Applied Physics Letters 98, 03410 (2011), DOI: 10.1063/1.3534806

- Contact: Dr. Martina Bieberle (Institute of Safety Research)

Current Flow at the Nano Level

Current Flow at the Nano Level

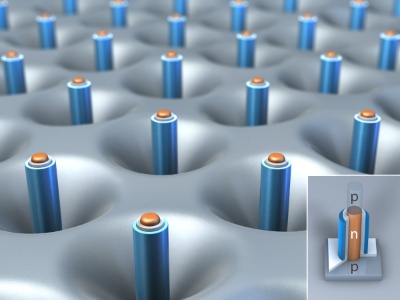

Silicon nanowires could become the memory chips of the future. For the first time ever, their electronic properties have been described in three dimensions

Silicon is the most important material for the production of computer chips and other electronic components. The industry has actually already advanced to the era of nanoelectronics because every single transistor among the billions of transistors on a chip has now reached the size of only 50 nanometers (one nanometer equals one millionth of a millimeter). When it comes to the needs and requirements of industry and the possibilities of research, then such miniaturization has to be pursued further. That is why new concepts are currently in progress. In order to save space, transistors could, for example, be arranged differently. At present, they are either laid flat next to or stacked on top of one another. Yet it is conceivable that they are rotated 90 degrees so that they protrude from the chip surface like tiny nanowires. In the future, it would, thus, be possible to place many innovative structures onto the surface of just a single transistor.

Even though silicon nanowires are already produced today, their electronic properties are not yet sufficiently known to build reliable transistors for a new generation of microchips. Electric current will not flow horizontally, but instead vertically inside these transistors which will become smaller and save more energy than this is the case today. In joint investigations, researchers from the Max Planck Institute of Microstructure Physics in Halle and the Helmholtz-Zentrum Dresden-Rossendorf discovered that the ability of silicon nanowires to conduct electric current and subsequently process information as transistors is limited. Should they be used as transistors in the future, then developers would have to pay careful attention to these findings.

In order for an electric current to flow inside the semiconductor material silicon, it has to be enriched with ions, which means it is charged with such particles as boron or phosphor. The scientists discovered that these particles do not stay where they are; instead, they move towards the edge of the nanowire; in other words, towards the surface. There, they become partially inactive and no longer contribute towards conductivity. A special method permitted the scientists to longitudinally remove the nanowires layer by layer during the measurements which, in turn, allowed them to take three-dimensional measurements. That is how they got 3D images of the conductivity inside a nanowire which only has the thickness of one 25,000th of a human hair.

- Publication: X. Ou, P. Das Kanungo, R. Kögler, P. Werner et al., Three-dimensional carrier profiling of individual Si nanowires by Scanning Spreading Resistance Microscopy, Advanced Materials 22(36), 4020-4024 (2010), DOI: 10.1002/ adma.201001086

- Contact: Dr. Reinhard Kögler (Institute of Ion Beam Physics and Materials Research)

Positrons Sniff Out Defects

Positrons Sniff Out Defects

A lab for the non-destructive testing of materials has been set up at the radiation source ELBE

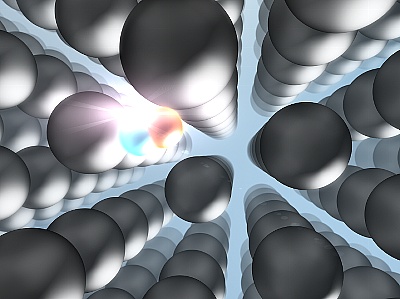

A new measuring station has been set up at the radiation source ELBE which provides a globally unique concept for the non-destructive testing of materials. It permits tests of compact mechanical components like, for example, toothed wheels or ball bearings as well as pulverized, liquid, or even radioactive samples. The procedure is extremely sensitive and able to detect the smallest defects such as, for example, gaps or foreign atoms in a crystal lattice.

Positrons, the positively charged antiparticles of electrons, serve as probes. But they can penetrate the material only by a few micrometers which is why only very thin samples have been scanned with a positron beam so far. However, the HZDR researchers do not use any external source; instead, they have the positrons created right in the material sample by directing braking radiation from the ELBE source to the sample. Due to the radiation, the positively charged particles are formed in the entire sample volume – even if the dimensions of this sample cover a range of several centimeters.

For the detection of defects, the scientists apply the so-called positron annihilation spectroscopy. The braking radiation of the ELBE source causes the material to initially produce positrons. If these positrons encounter electrons with the appropriate spin, both particles annihilate each other (annihilation) while, at the same time, emitting two photons which fly away in opposite directions. Detector pairs arranged around the sample register these light flashes and record how quickly the positrons annihilate. Because even tiny defects and very low defect concentrations inside the material influence the life cycle of positrons, the researchers are, thus, able to gain valuable insights into the atomic structure of the sample; for example, to what extent a steel sample changes under mechanical stress. The new lab is used for interdisciplinary projects. For example, the HZDR safety researchers use the lab for analyzing the quality and characteristics of reactor steels.

- Publication: M. Butterling et al., Positron Annihilation Spectroscopy using high-energy photons, Physica Status Solidi A 207, 334 (2010), DOI: 10.1002/pssa.200925340

- Contact: Maik Butterling (Institute of Radiation Physics)

Customized Magnetic Fields

Customized Magnetic Fields

In cooperation with the Leibniz Institute for Solid State and Materials Research Dresden (IFW), magnetic fields are used for the production of titanium-aluminum monocrystals

Metallic alloys from titanium and aluminum are particularly popular materials in the aviation and automobile industries. Because even though they are lighter than the high temperature materials which are commonly used in these branches, they exhibit the same strength. In order to further optimize the specific properties of these materials, they have to be available as monocrystals; which means their components have to be arranged in a single, coherent, and uniform crystal lattice. Only such special structures allow the properties of a material to be measured in their pure form – which is also the basis for studying and improving the quality and characteristics of non monocrystalline materials.

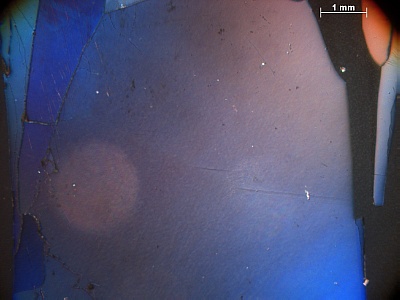

Monocrystalline compounds made from titanium and aluminum or other materials are, depending on their specific composition, not always easy to produce. Scientists at the Leibniz Institute for Solid State and Materials Research Dresden (IFW) and the Helmholtz-Zentrum Dresden-Rossendorf use customized magnetic fields to grow perfect monocrystals. Magnetic fields can have an impact on the direction into which liquid metals flow, for example, during crystal growth, and on the speed at which they move in the course of this process. The Helmholtz researchers have calculated what such a magnetic field actually has to “look” like in order to precisely control the interface between liquid and solid metals which is decisive for the formation of monocrystals. They, thus, created the prerequisites for a new, patented procedure with which crystals are grown at the IFW. It is based on a thin metal rod which is slowly melted and solidified repeatedly. The rod is surrounded by two magnetic coils which, on the one hand, produce the heat required for melting the metal and, on the other hand, generate a magnetic field which stirs the liquid metal in the melting zone. The researchers have become so successful with their method that they are now even able to grow complex metallic monocrystals and analyze their properties.

- Publication: R. Hermann, G. Gerbeth et al., Convectional controlled crystalmelt interface using two-phase radio-frequency electromagnetic heating, Journal of Materials Science 45, 2228-2232 (2010), DOI: 10.1007/s10853-009-4117-0

- Contact: Dr. Gunter Gerbeth (Institute of Safety Research)